8mm A10 Degree Tungsten Carbide Insert Carbide Milling Tools

Product Details:

| Place of Origin: | Zhuzhou, China |

| Brand Name: | JWE |

| Certification: | ISO9001-2015 |

| Model Number: | B1 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1KG |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Carton Box |

| Delivery Time: | 5-15 days |

| Payment Terms: | T/T |

| Supply Ability: | 50T per month |

|

Detail Information |

|||

| Material: | Tungsten Carbide | Product Name: | Carbide BrazedTips |

|---|---|---|---|

| Grade: | YG8 / Customized | Place Of Origin: | Zhuzhou, China |

| Certification: | ISO9001-2015 | Sample: | Avilable |

| Package: | Carton Box | Stock: | Available |

| High Light: | 8mm Tungsten Carbide Insert,a10 Degree Tungsten Carbide Insert,8mm Carbide Milling Tools |

||

Product Description

Carbide Brazed Tips B1 For Making Forming Turning Tools Planning And Milling Tools For Machining Dove Tail Grooves

Application: Brazing Carbide Inserts For Making Forming Turning Tools Planning And Milling Tools For Machining Dove Tail Grooves

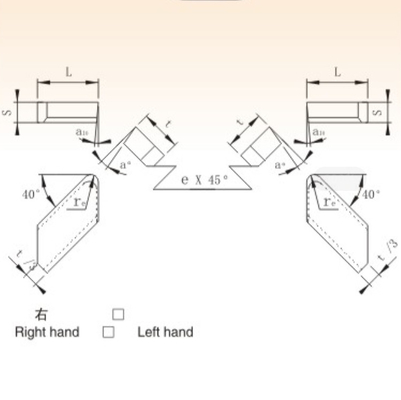

| Type | Dimension(mm) | |||||||

| R.H. | L.H. | L | t | S | rε | e | a° | a₁° |

| B108 | - | 8 | 6 | 3 | 1.5 | - | 0 | 0 |

| B112 | B112Z | 12 | 8 | 4 | 1.5 | 1.0 | 10 | 5 |

| B116 | B116Z | 16 | 10 | 5 | 1.5 | 1.0 | 10 | 5 |

| B120 | B120Z | 20 | 14 | 6 | 1.5 | 1.0 | 10 | 5 |

| B120A | B120AZ | 20 | 16 | 7 | 1.5 | 1.5 | 10 | 5 |

| B125 | B125Z | 25 | 14 | 5.0 | 1.5 | 1.5 | 10 | 5 |

| B125A | B125AZ | 25 | 18 | 8 | 1.5 | 1.5 | 10 | 5 |

| B130 | B130Z | 30 | 20 | 8 | 1.5 | 1.5 | 10 | 5 |

Drawings as below:

![]()

Production and test of Carbide Brazed Tips:

1)Carbide Brazed Tips will start to prepare the powder as per the customer’s requirement with our wet-grinding machine

2) Before mass production, we need to do a trial pressing and sintering, and we check the appearances and the sizes of the samples with a micrometer to ensure that the requirements of the drawings can be met before batch production

3) Bulk production, press the raw materials to shape blanks, and carbide tips must be passed by semi-finished inspection.

4) sinter blanks to finish (HIP) and finished products inspection to ensure the best quality and production capacity.